Case Study: Using ROCK LiDAR to Inspect Power Lines Across California

- Vincent Aurand

- Mar 1, 2023

- 4 min read

Updated: Aug 2, 2023

California-based company Surefire tackles complex construction management projects. When one of the state’s largest utility companies approached them with a series of inspection projects spanning much of the north coastal region of California, the team couldn’t pass up the opportunity. So how did Surefire approach this extensive power line inspection project? One drone LiDAR flight at a time.

PROJECT SNAPSHOT

ROCK Client: Surefire

Surefire Client: One of California’s largest utility agencies

Assignment: Inspect a large series of powerlines to ensure the utilities comply with all California Public Utilities Commission regulations and requirements.

Result: Surefire was able to capture accurate point cloud data efficiently and safely and delivered the data in a preferred format for the utility industry.

ROCK CLIENT: Surefire in Temecula, California

Surefire is a fully-integrated construction management and technical service company. Its team of highly-trained, knowledgeable inspectors and managers specializes in design and construction quality-control services for major utilities throughout California.

Surefire mainly uses drone LiDAR on transmission jobs, scanning powerlines and converting point cloud data into PLS-CADD models for utility agencies’ use.

We spoke with Noah Carr, Drone Division Manager at Surefire, for this case study.

EQUIPMENT USED

Carr and his crew used a DJI M300 RTK drone with ROCK Robotic R2A LiDAR hardware.

PROJECT BACKGROUND

Surefire is continually collaborating with one of California's leading utility providers to develop a system for efficiently gathering as-built data that complies with all California Public Utilities Commission regulations and requirements (this project is still ongoing as of the time the case study was published).

With the rise in wildfires and their possible link to power lines, there is a pressing need to capture this information as quickly as possible, beginning with collecting data from the foundation, steel, and wire. A drone then performs a LiDAR flight to complete the process. The ultimate aim is to provide engineers with accurate and up-to-date information for their models. To accomplish this, a rapid turnaround on capturing as-built data is required for new construction.

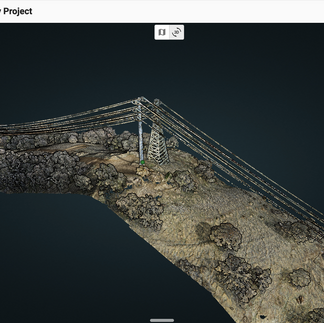

The Hilltop Utility Project posed a unique set of challenges for the Surefire team. The tower they were tasked with scanning was situated atop a hill with a 500-foot elevation difference from the base. Because of the specifications mandated, the crew needed to capture data from one tower ahead of the line and one tower on the back of the line.

This presented an obstacle. The drone was not visible from the base of the peak, and a receiver connection was impossible due to the steep drop-off on the other side of the hill. In addition, continuous rainfall in the days leading up to the project rendered the road leading up to the tower impassable for vehicles and barely traversable on foot due to its steep and muddy condition. In contrast, projects on flat terrain are generally less complicated, allowing larger areas to be covered in a shorter amount of time.

SOLUTION

The Surefire team had to overcome the connection issues and visual line-of-sight challenges. Initially, they couldn’t take off from the peak because there was no way to get the equipment up there, so they opted to set up the drone at the base of one side of the hill. Subsequently, they embarked on a grueling hike up the muddy incline with the controller and laptop, covering over a mile to reach the top. However, an error message popped up as UgCS would not stay connected in the relatively remote area outside of the nearest town.

Despite attempting to troubleshoot their UgCS connection for around 30 minutes, the team concluded that flying the site manually was the only option. However, manual flying of powerlines posed its own set of challenges, particularly when trying to maintain a straight line while changing elevation the whole flight; the corridor had an elevation change of 400ft in less than a mile. To address this, Carr launched the drone from the hill's peak, with a visual observer stationed at the bottom. Carr then repeated the manual flight path four times to ensure adequate overlap and sufficient width coverage of the corridor.

Although the operation was tricky, the Surefire team successfully completed the data capture. They subsequently trekked down the hill's backside to retrieve their GCP targets and back up again to complete the project. Despite the challenges, the data turned out to be accurate and error-free.

RESULTS

Using LiDAR technology for the project proved to be a more efficient and cost-effective solution compared to the alternative. If the team hadn't used LiDAR for the project, the utility would have had to use a helicopter to scan just one or two towers which is not cost effective compared to drones. Thanks to the use of a drone, however, there was no need for any utility disruptions (or helicopters), and the project was able to proceed smoothly without any negative impacts on the surrounding community.

This ongoing utility inspection project will result in faster data for the utility and a safer energy grid for the community the utilities serve. The Hilltop Utility Project is only one piece of this much larger puzzle, which will provide a trove of helpful data to Surefire’s utility client.

Surefire didn’t order any deliverables from ROCK Cloud for this project, as their client requested data in PLS-CADD files directly from the point cloud data. “If we were to use a deliverable from ROCK Cloud,” offered Carr, “it would definitely be the vegetation management deliverable, and we will be using that soon later on in the larger scope of the project."

The [ROCK] hardware has worked great for us so far, and the best thing has been the team behind the scenes and the customer support that ROCK Robotic has provided.

Surefire Consulting was an early adopter of ROCK hardware and ROCK Cloud software. Carr noted that “The hardware has worked great for us so far, and the best thing has been the team behind the scenes and the customer support that ROCK Robotic has provided. They are able to offer high-quality customer service, which provides a ton of value to my team.”

Start your 14-day free trial of ROCK Cloud today at cloud.rockrobotic.com.

Commentaires